Our insert molding technology, we have developed through many years of responding to diverse requests, has a proven track record of meeting the demands of prominent companies in a variety of fields.

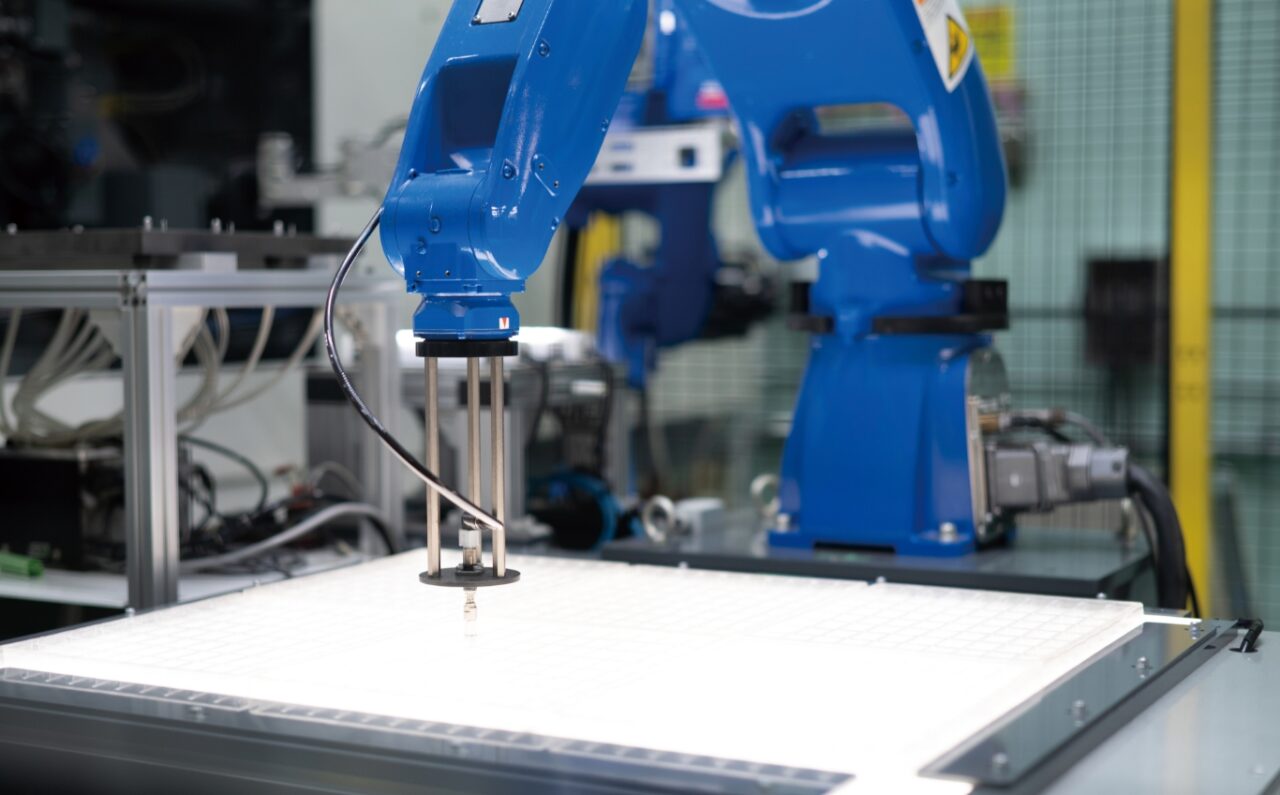

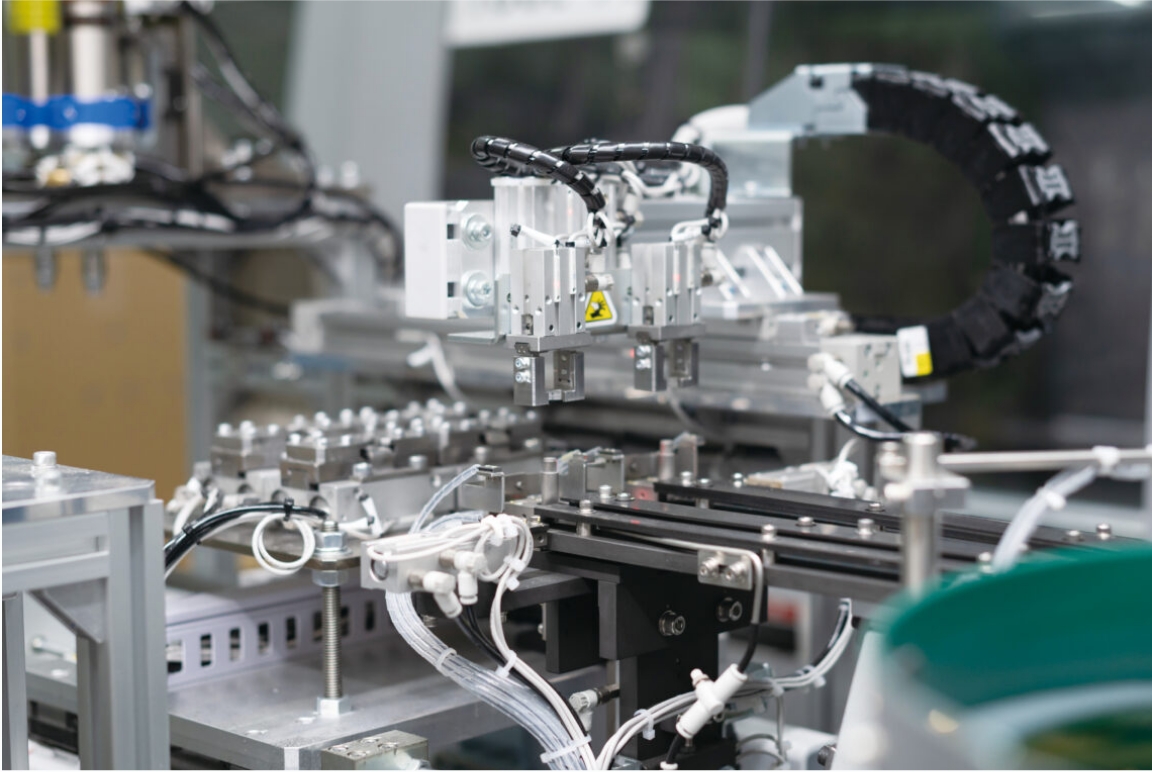

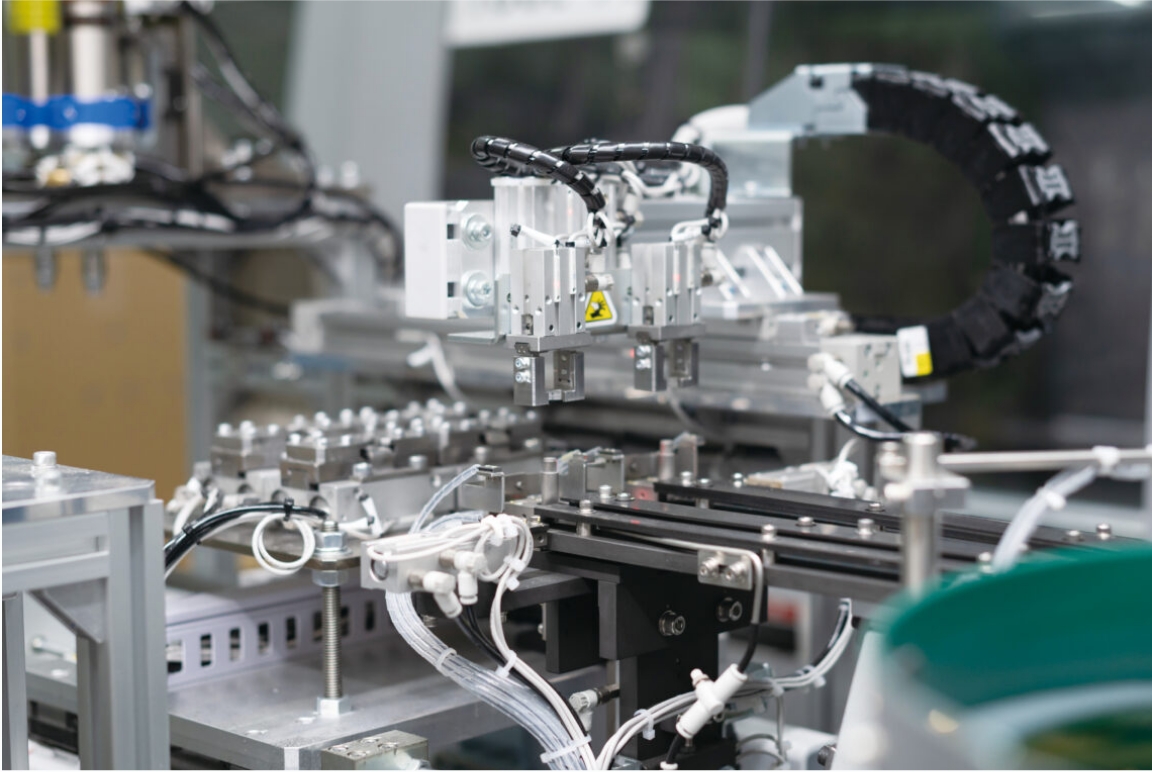

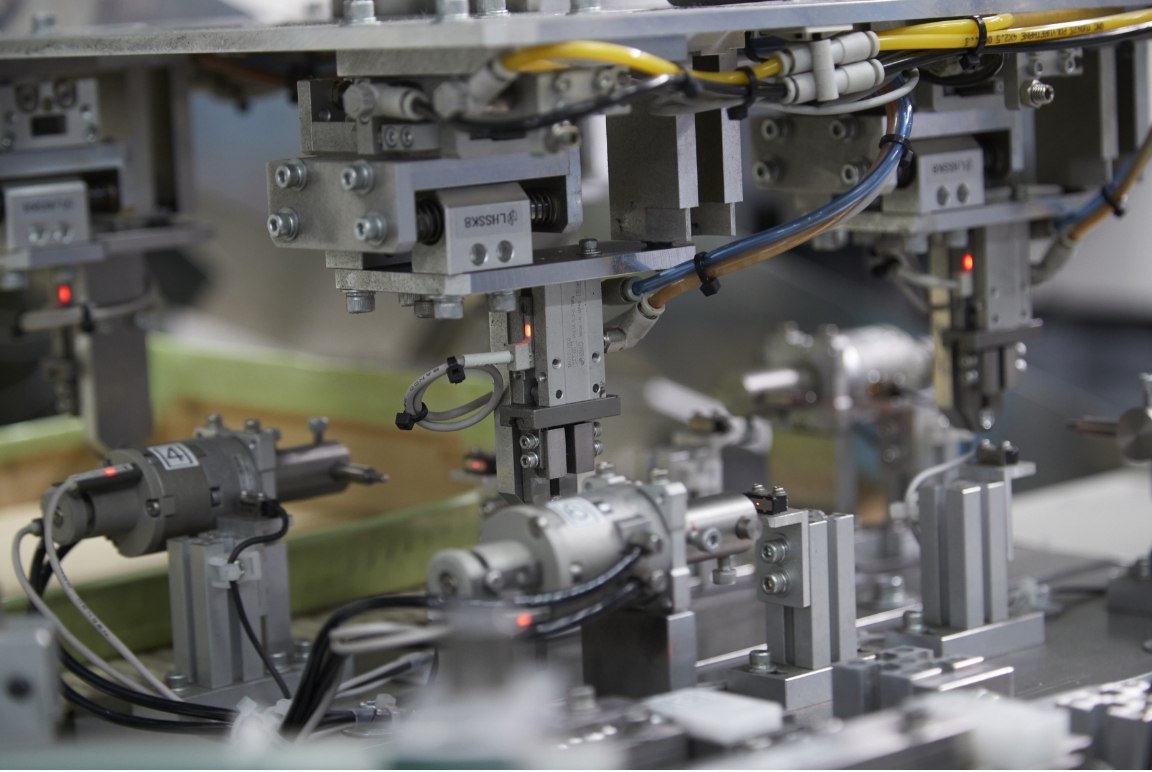

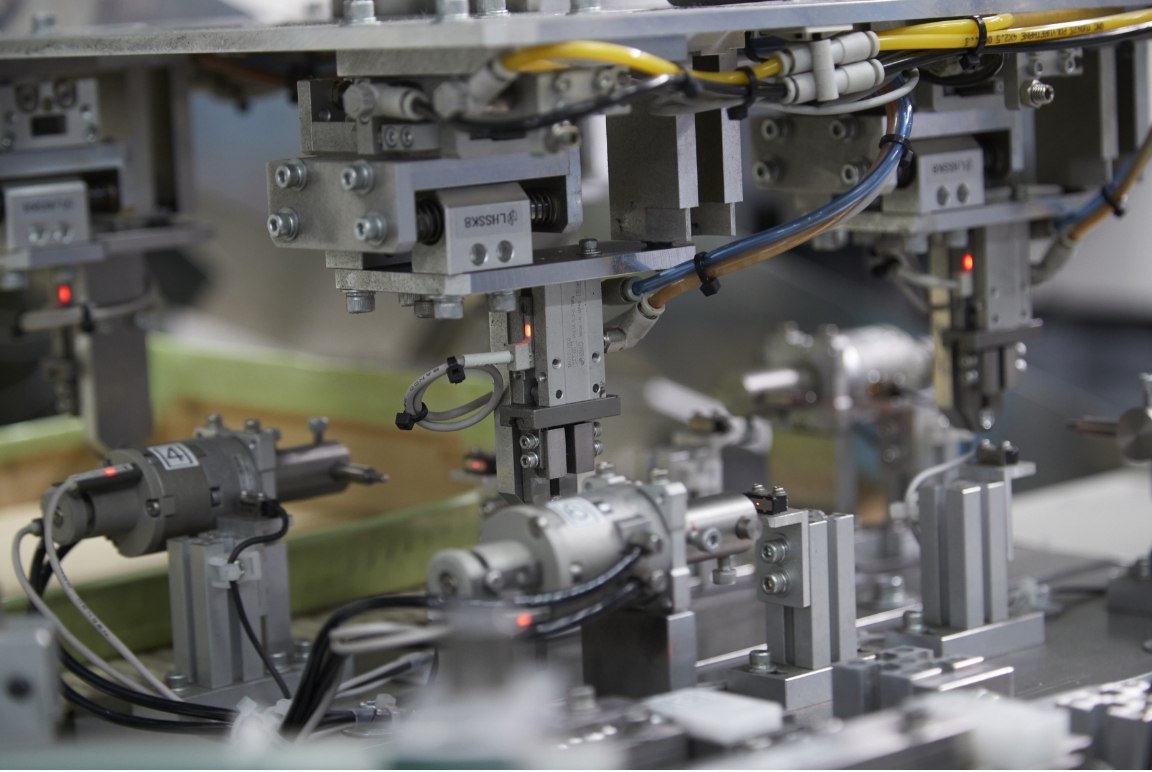

Leading the way in full automation to ensure exceptional molded products, we have also been dedicated to enhancing the skills of our production staff.

Our Strengths in

Insert Molding

- Insert Molding by Automation

Typically, plastic injection molders encounter challenges when attempting to enhance productivity and uphold quality in insert molding.

Reason- To insert metal fittings etc. into a mold, the manufacturer needs to present at all times to check on the progress in order to achieve a high-quality product.

- Since quality is determined by human hands, the number of products produced each day varies based on the level of skill.

- The process tends to become unstable depending on the availability of manufacturers and their fatigue levels.

Insert molding is an effective technology for transforming metal products into resin, and the intention is to also replace other parts with resin too.

High quality insert molding

High quality insert molding

Insert moulding is an effective technology for converting metal products to resin, but the resin parts other than the insert fittings are also assumed to be metal substitutes.

Reason- This is because resins with high strength and high dimensional accuracy are often selected.

- Resins with high strength and dimensional accuracy often incorporate a significant amount of fibers, such as glass and carbon.

- Resins with added large amounts of glass and carbon, will scrape the screw cylinder in a general molding machine, which will have a negative impact on the products and cause the molding machine to wear out and require replacement much earlier.

All of our molding machines incorporate anti-corrosion and wear-resistant screw cylinders, so we can manufacture products without worrying about large amounts of additive materials such as glass and carbon.

- Highly versatile insert molding

Manufacturers that perform insert molding mainly use vertical molding machines.

Reason- Simply because it’s the current standard.

- Vertical molding machines are stable because the metal fittings are inserted into the mold using gravity.

However, we have purposely introduced a “horizontal molding machine” to make effective use of limited space and produce molded products tailored to your requirements, irrespective of size.The versatility of the ‘horizontal molding machine’ allows it to be applied not only to the production of specific molded products but also to a broader range of molded items. In addition, it is a fully automatic molding system that operates 24 hours a day and is suitable for improving QCD and reducing process load rates, making it an environment unique to our company.

List of compatible materials

- PA6

- PA66

- PET

- PE

- PA11

- PA12

- PC

- PPS

- PEEK

- PMMA

- PEI

- PSU

- LCP

- PAI

- POM

- TPE

- PBT

- PSF

- ABS

- PP

- PS

- PPE

- other

Production results

Bicycle parts

Bicycle parts Automated mesh filter insert molding

Automated mesh filter insert molding Help mark

Help mark