Insert molding, which was difficult to achieve, and engineering plastic molding, which other companies avoided, are challenges that our technical expertise, innovative proposals, and teamwork have conquered. We excel at producing high-quality molded products that align with your requirements.

We are eager to take on tasks that others shy away from or reject.

- Main production fields

- -Road bike parts

- -Fishing gear

- -Mechanical parts

- -Industrial products

*Fields to be addressed in the future

We will continue to push forward to make our goals a reality, with a strong incentive be involved in the manufacturing of medical devices.In addition, we can manufacture a wide range of products regardless of industry. Please contact us for more information! - Regarding prototype support

- -We have the capability to transfer the production of various molding processes that were previously unachievable.

- -Possible to make resin from metal, ceramic, glass, etc.

- -We can provide customized cost reduction proposals based on the prototype specifications.

- -We can consider the functionality of the facility according to the request details.

- Production rangeMaximum processing precision

- -~130t moulding machine ±0.03 mm available

- -~230t moulding machine ±0.05 mm available

Minimum & maximum lot size-From 1 piece and above. *Please feel free to contact us regarding the maximum number of lots.

Minimum & maximum Size・W10×D10×H0.5mm ~ W400×D300×H300mm*There are aspects that cannot be generalized, so please feel free to consult with us anytime.

Plate thickness-t0.5~t50*There are aspects that cannot be generalized, so please feel free to consult with us anytime.

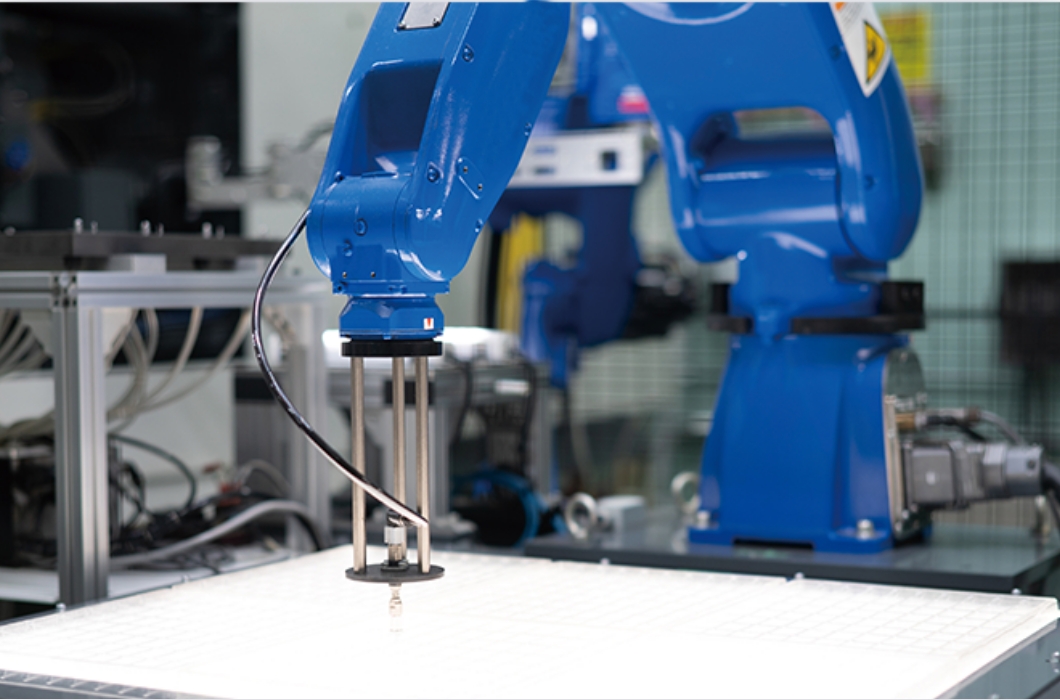

Insert molding

Insert moldingTraditionally, insert molding has been a manual process, relying on human hands.

However, we have successfully implemented unmanned, automatic operations for insert molding by integrating robots and human expertise.

This enables us to provide high-quality products with efficiency. Engineering plastic molding

Engineering plastic moldingOur company has created an environment suitable for engineering plastic molding.

All molding machines are designed for high temperatures, and we also have mold temperature controllers that can handle high temperatures.

We also carry a variety of material dryers and dehumidifying dryers that are essential for engineering plastic molding. Factory/equipment introduction

Factory/equipment introductionWe have installed the latest equipment that is not readily available at other manufacturers, and strive to improve quality and productivity.

We use our creativity and ingenuity to create the optimal environment within the limited space available. Poco a poco

Poco a pocoOur educational toy brand is unique to our company, which specializes in engineering plastic molding.

Based on the concept of “To form a future with kindness,” we strive to develop products that are fun and exciting for children.