Our company was one of the first to engage in mechanization using robots and unmanned autonomous driving,

and has strived to improve productivity and maintain quality.

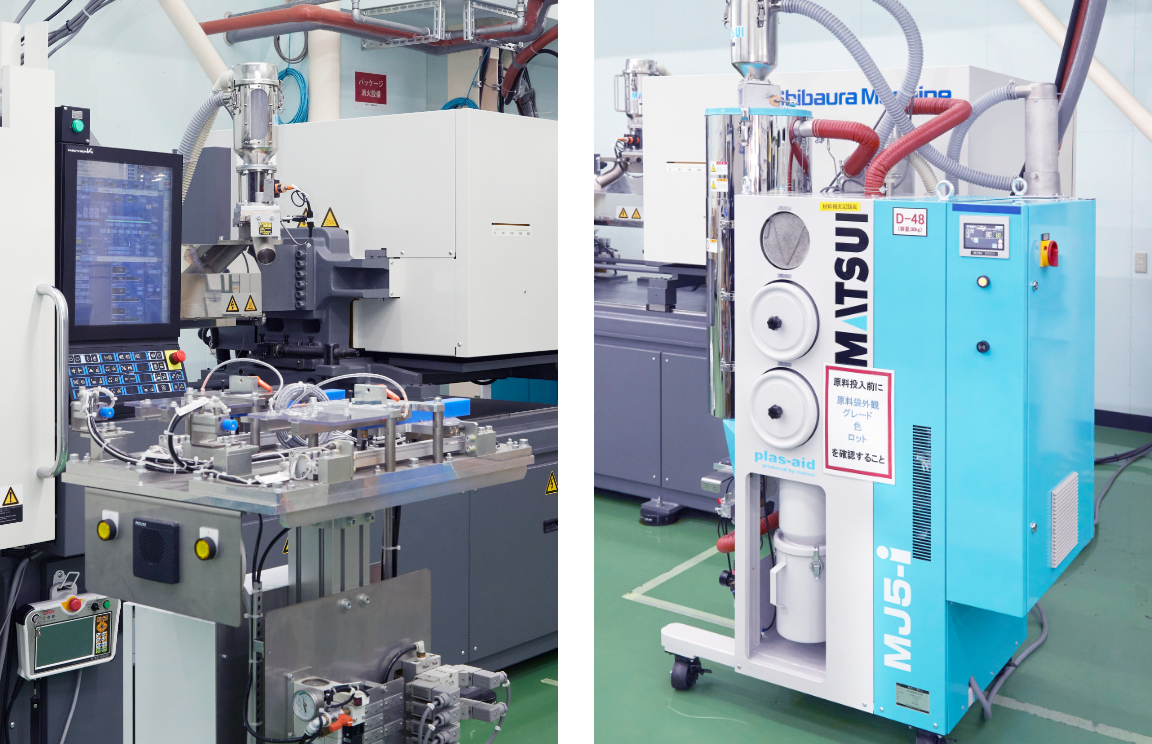

With our extensive equipment, we can swiftly produce high-quality molded products and cater to a wide range of requests.

The initiatives our company is undertaking, such as the “automation of production lines,” “24-hour unmanned production capabilities,” and “mechanization through the introduction of robots,” offer numerous advantages and possibilities.

We have incorporated machines rarely seen in the industry at other companies and invested in state-of-the-art equipment.

Our company is actively promoting the automation of production lines, enabling 24-hour unmanned operation, and leveraging our expertise in insert molding. Through these automation and mechanization efforts, we have achieved the production of molded products that were previously unprecedented.

Furthermore, with a fully automated manufacturing line, we have the capability to operate 24 hours a day, 365 days a year. The introduction of robots for mechanization offers numerous benefits and possibilities.Manufacturing/auxiliary equipment list

*Please scroll horizontally to view.

Manufacturer Equipment name Model Number of units Specification SHIBAURA MACHINE CO., LTD. All-electric injection molding machine EC50SX-1Y 1 50t EC75SX-1.5Y Other 3 75t EC100SXⅢ-2Y 1 100t EC130SX-4Y Other 7 130t EC180SXⅢ-6Y Other 11 180t EC230SXⅢ-6Y Other 9 230t EC450-26A 1 450t STAR SEIKI CO., LTD. Retrieval robot GXW-800SRVIP Other 32 YASKAWA Electric Corporation Industrial robot GP7 1 GP12 1 MATSUI MFG. CO., LTD. Dehumidifying hot air dryer MJ5-i-150-J Other 32 Box dryer PO-80-J 2 PO-50-J 1 Temperature controller MC5-G3-55HH180 Other 12 Maximum temperature:180℃ Crusher SMGL3-G1 1 Mass type compounding device JCW2-i-053-JB-31-J Other 2 KAWATA MFG. CO.,LTD. Temperature controller TW-5009/180 Other 33 Maximum temperature:180℃ NISSUI CHEMICAL INDUSTRIES CO.,LTD. Crusher SA-030 1 STOLZ Co., Ltd. Crusher SA-24 Other 3 Horai Co., Ltd. Crusher P-1328 Other 8 *Please scroll horizontally to view.

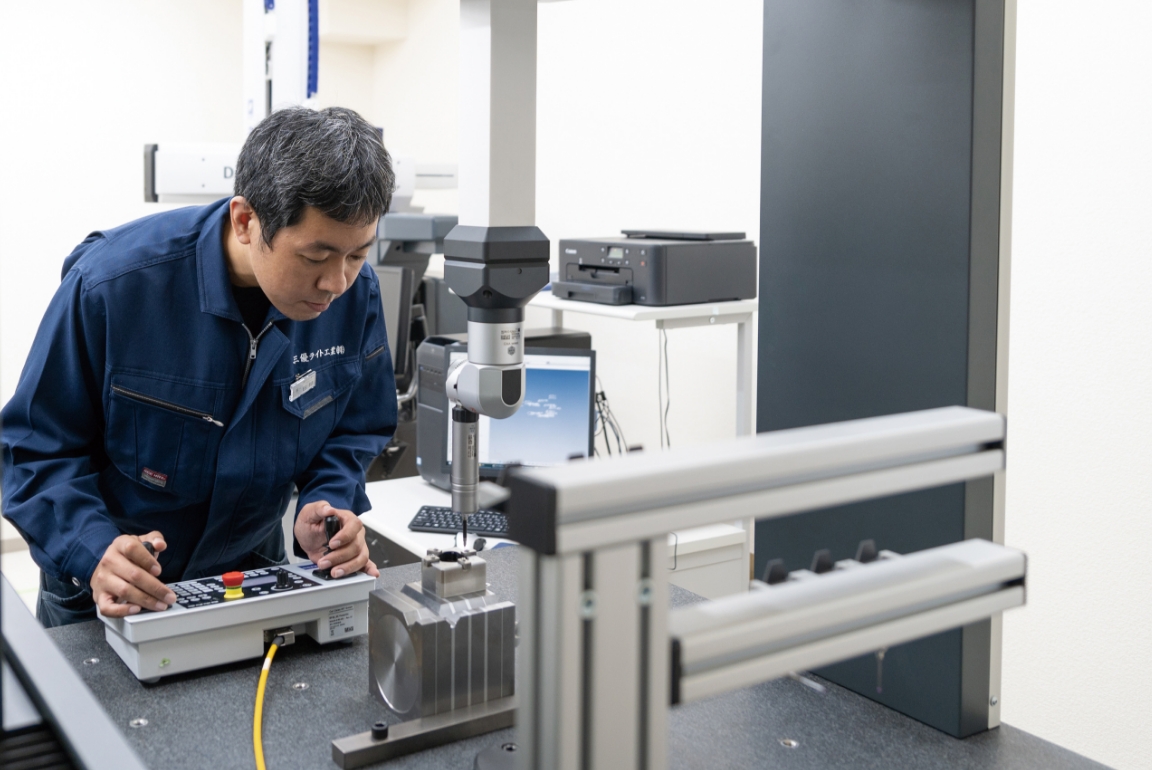

List of inspection and measurement equipment

*Please scroll horizontally to view.

Manufacturer Equipment name Model Number of units Specification TOKYO SEIMITSU CO., LTD. 3D coordinate measuring machine DURAMAX5/5/5 1 Measurement range

500×500×500CONTURA 7/10/6 1 Measurement range

700×1000×600RF Co.,Ltd. X-ray computed tomography device NAOMi-CT 1 Measurement range

φ68×45~49 ㎜KEYENCE CORPORATION. Image dimension measuring device IM-6225T 1 Measurement range

φ100×L200 ㎜//Minimum scale 0.001㎜LM-1100 1 Measurement range

φ100×L200 ㎜//Minimum scale 0.001㎜NIKON CORPORATION Measuring microscope MM-800/LMFA 1 Measurement range

200×L200 ㎜//Minimum scale 0.001㎜*Please scroll horizontally to view.

Traditionally, insert molding relied on manual labor, but with the increasing complexity of product shapes and the demand for multiple types of metal fittings in a single product, quality became less stable.

To address this, we are prioritizing thorough automation and mechanization, reducing dependence on manual intervention and establishing an environment conducive to delivering consistent quality.

Our company employs high-temperature designed molding machines, and all equipment, including attached mold temperature controllers and material dehumidifying dryers, is engineered to handle engineering plastics.

We consistently invest in facility additions and updates, aiming to enhance our overall environment and sustain a high level of quality.The key to automating a production line lies in the design and maintenance of auxiliary equipment and robots.

The advancement of mechanization and automation hinges on the ability to analyze the optimal process based on part shapes and equipment characteristics, design the equipment accordingly, and consistently maintain technology to prevent issues.

Our dedicated staff team, with its extensive experience and technical expertise, is the driving force behind these capabilities.

Plastic serves as an indispensable material in a wide array of applications across industrial fields, spanning from industrial to household goods.

At our company, we utilize general-purpose materials like polyethylene (PE) and polypropylene (PP), along with advanced resins such as polyamide (PA), polycarbonate (PC), and polyphenylene sulfide (PPS), incorporating carbon fiber and glass fiber as metal substitutes.

With an inventory of over 300 molding materials, including engineering plastics (super engineering plastics), we have established a responsive system to promptly address requests from various companies.

Additionally, we have embraced environmentally friendly practices by introducing biomass plastics containing 51% rice husk.

Our proprietary ‘rice husk resin,’ available in 12 colors, is utilized in our in-house brand ‘Poco a poco’ products.